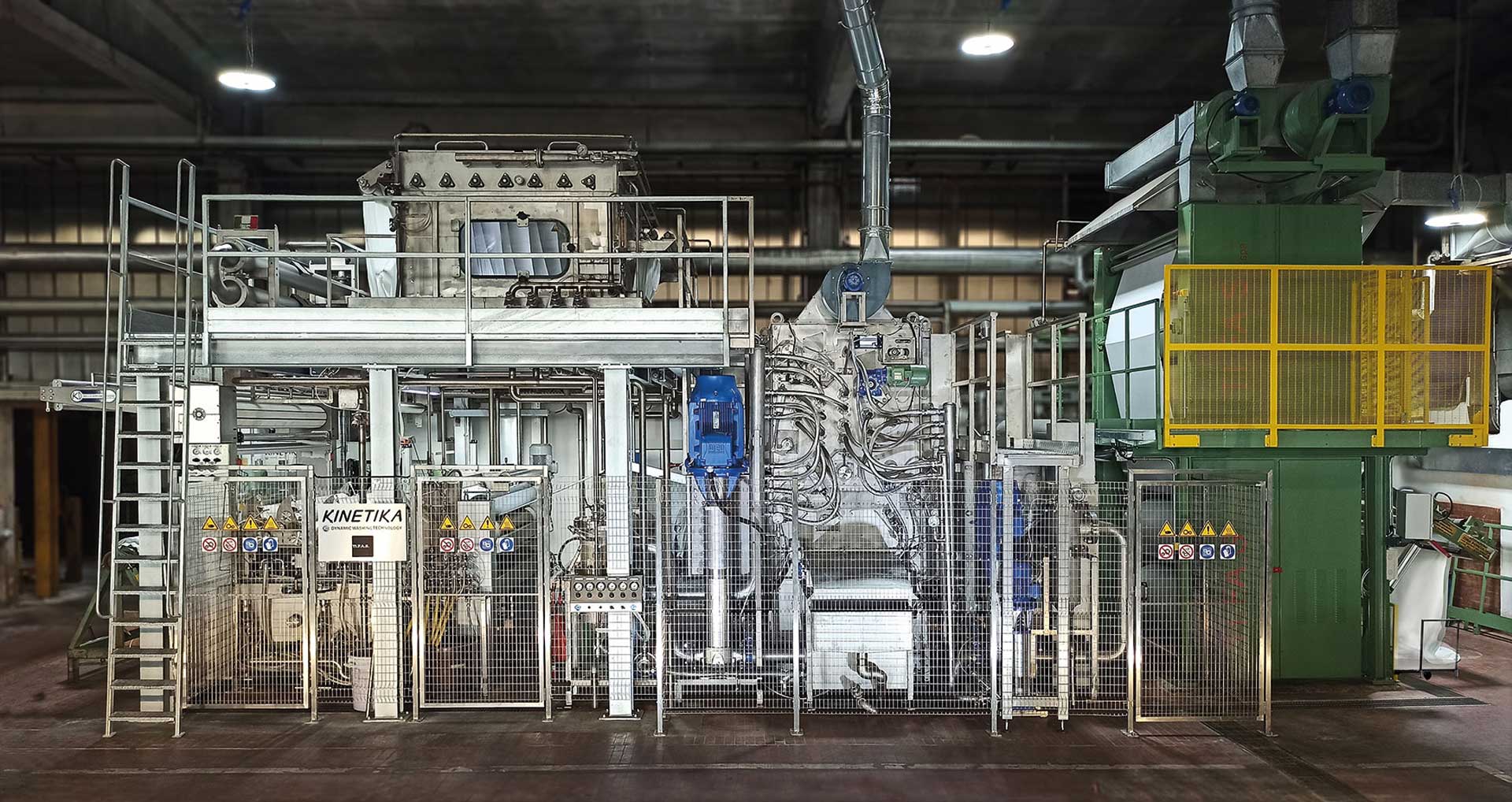

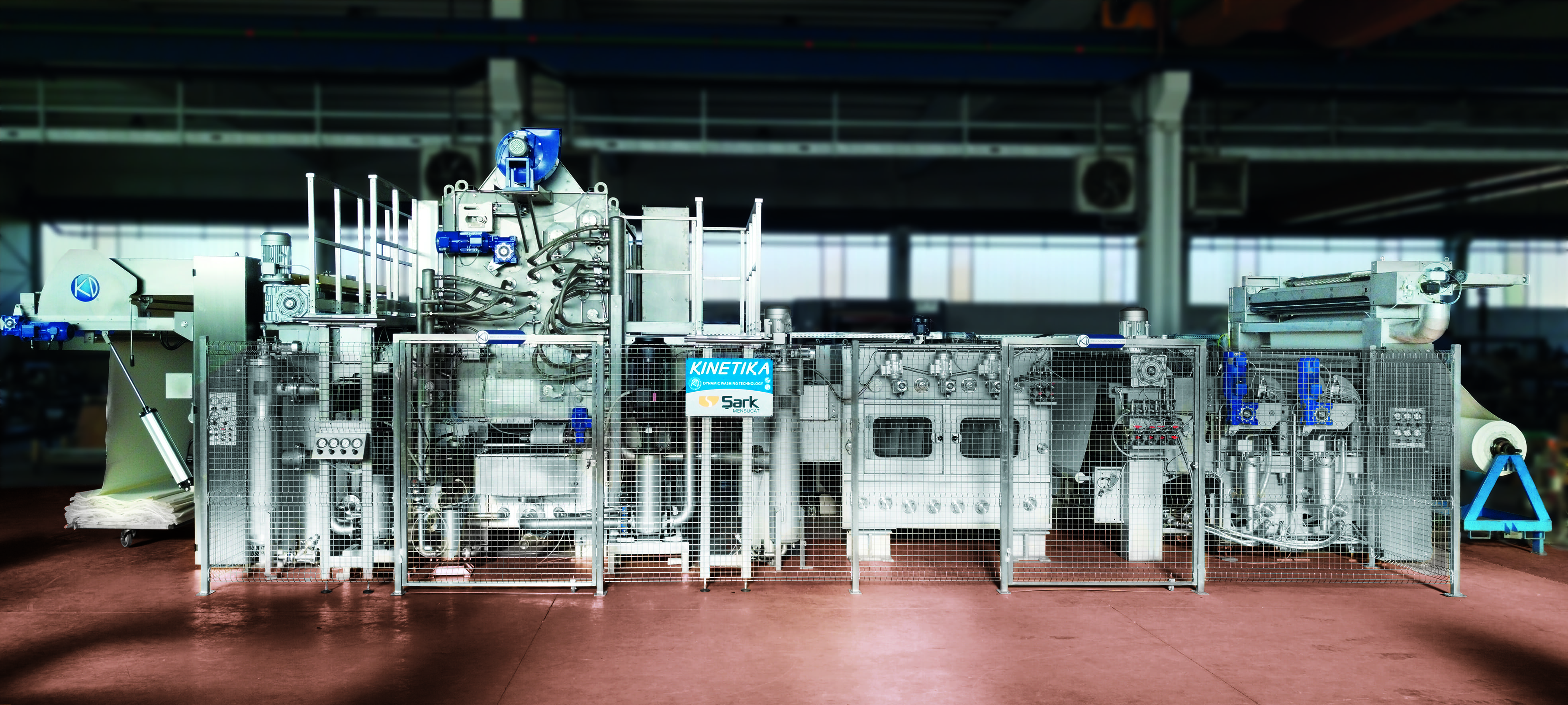

Continuous open width washing machine

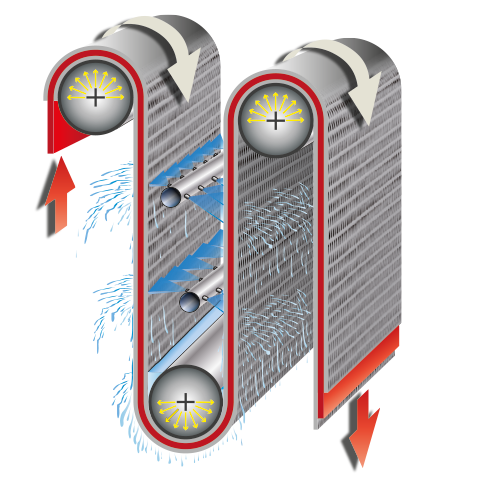

Kinetika is a new continuous washing system, based on a patented principle that exploits the potential of the kinetic energy of water.

with this exclusive dynamic washing process the fabric is crossed by jets of high pressure fluid while it is carried by a pair of permeable belts that avoid stretches or the formation of folds.

Kinetika guarantees an ideal tensionless wash for all stretch fabrics (natural stretch or with elastomer), the versatility of dynamic washing is confirmed by several end users active in the following fields: high fashion fabrics of noble fibers, extra-fine menswear fabrics, fabrics for linings, furniture fabrics, automotive sector, denim fabrics.

TESTIMONIALS

To wash its own fabrics made with very fine wool, Drago Spa (Biella) wanted to be first to test the dynamic washing performance of Kinetika. After a period of tests performed in strict collaboration with the technical experts of Biella Shrunk Process, the Drago style-office managers enthusiastically approved the results obtained.

Paolo Drago says: “We were looking for a machine with compact dimensions, but which was at the same time versatile and efficient, able to wash not only fine worsted textiles but – above all for the summer collection – also linens and silks… Kinetika gave surprising results!”.

Pasquale Panetta, director of the finishing department adds: “We are amazed by the total absence of tension in the fabric, which allows to avoid any elongation and creasing formation, moreover the textiles washed with Kinetika present a feel which surprised us, in that it is softer compared to that usually obtained with traditional continuous washing treatments, nevertheless the weaving of the yarns remains very neat and clean”.

Lanificio Ferla (Valdilana – Biella) represents excellence in the high fashion fabrics sector, inspired by a perfect synthesis between the heritage of the best textile tradition and a constant propensity for product innovation.

For Ferla Spa , the purchase of Kinetika has made it possible to enhance the weaves of fabrics, made with refined yarns of precious raw materials: thanks to this new dynamic high pressure washing technique, the fabric undergoes an initial processing that enhances its softness and improves the vividness of the colors.

Ti.F.A.S. (Lurate Caccivio – Como) expresses the state of the art in the field of dyeing and finishing of synthetic and artificial fabrics for both clothing and lining: viscose, cupro, nylon, polyester, together with other natural fibers, are subject to treatments and dyes that derive from skills acquired in over fifty years of activity, taking advantage of a model structure that incorporates a certified laboratory.

Ti.F.A.S. Spa has achieved the target of energy efficiency and reduced environmental impact. Kinetika is, in fact, able to wash fabrics after dyeing at a speed of up to 80 m/min, with a water consumption of about 500 liters/hour.

The fabric transport belts, combined with high pressure jets, are an ideal solution for effectively washing even the finest and most delicate fabrics.

Since 1948 Lanificio di Pray Spa has been producing woolen and worsted fabrics for men's clothing, made of fine natural fibers such as cashmere, wool, alpaca, linen and silk, which define a modern style of great personality, appreciated by clothing, accessories and technical fabrics buyers.

The Kinetika high pressure washing jets allowed to partially replace discontinuous processes, with the benefit of productivity and quality improvement.

The overall reduced dimensions was a determining factor in the choice of the new Kinetika washing technology, that includes three interconnected units: fabric impregnation and soaping + high-pressure washing + steam treatment for fixing.

Tessitura di Crevacuore Spa is specialized in the production of high-end fabrics used for making dresses that parade all over the world in events dedicated to prêt-à-porter and high fashion.

Tessitura di Crevacuore staff confirms that thanks to the new dynamic high-pressure washing, it has been possible to drastically reduce the concentration of soap, with a positive environmental impact and a reduction of waste water treatment cost.

The effectiveness of the dynamic washing, combined with the use of a mineral detergent, free of surfactants, has made it possible to achieve excellent levels of cleanliness of the fabric; the process efficiency is confirmed by the reduced water consumption, combined with an average of 20% increase in productivity.

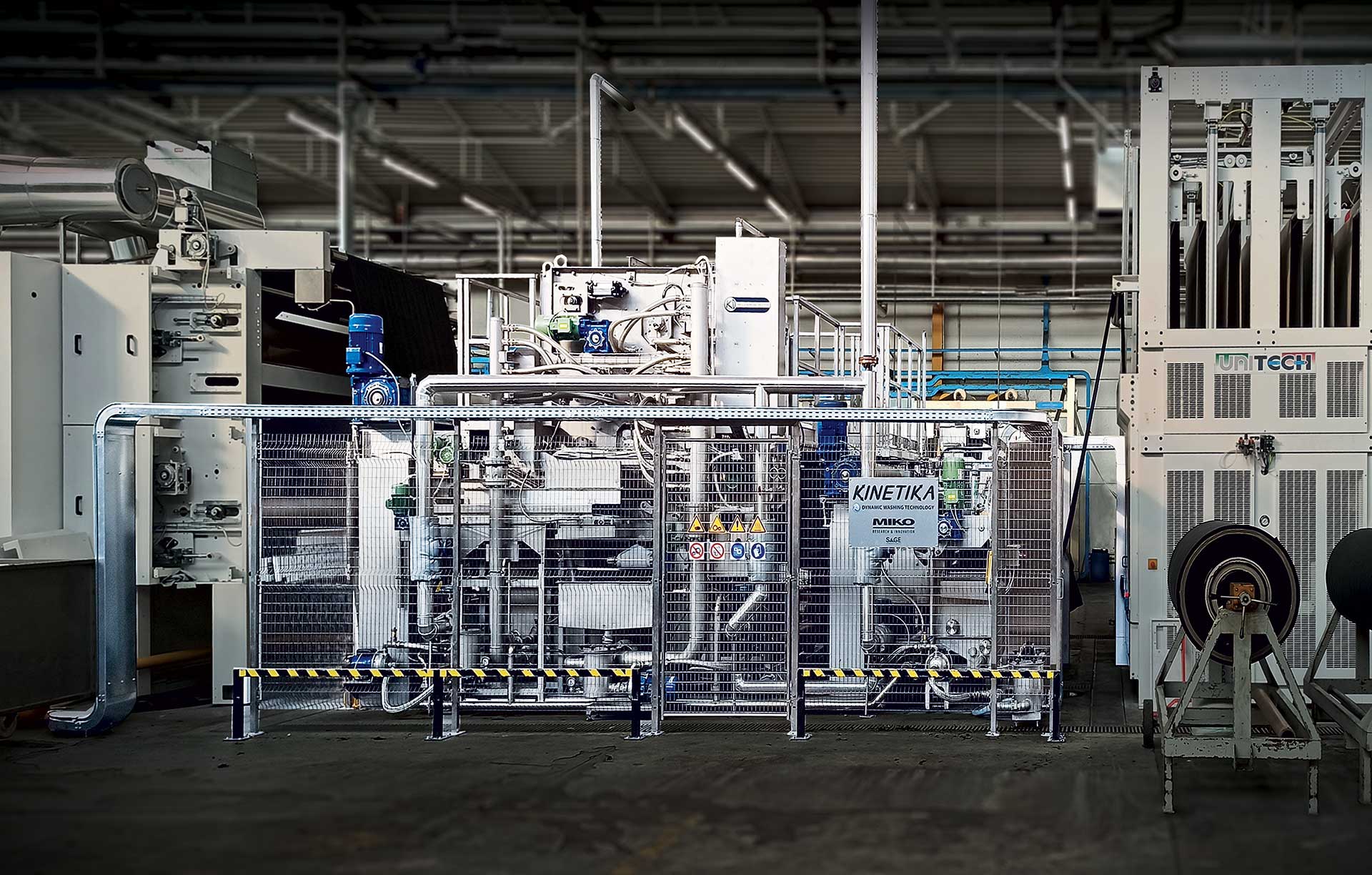

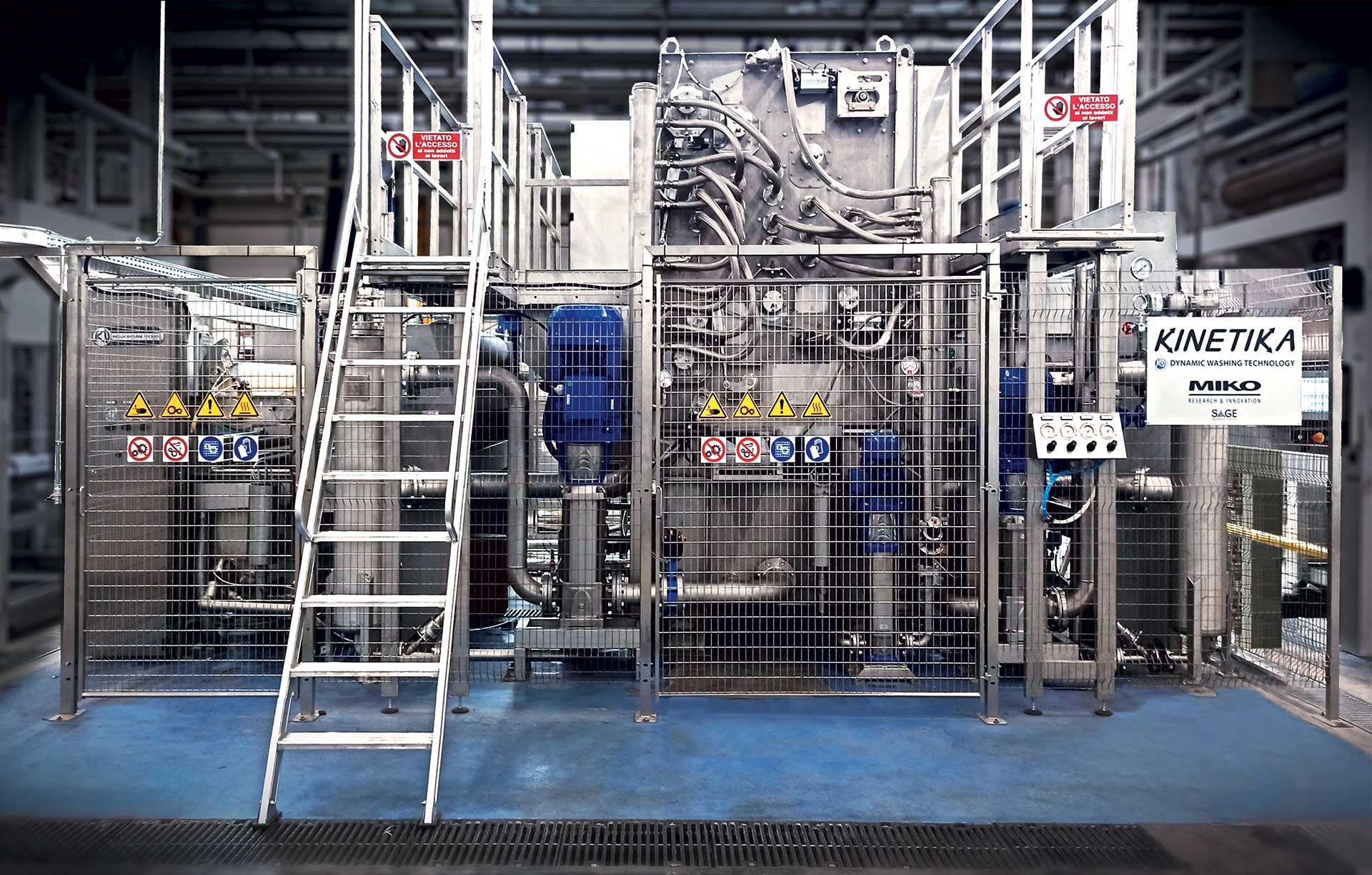

Miko S.r.l. was founded in 1997 by establishing its headquarters in Gorizia.

Since the dawn of its activity, the company has been focused on the production of Dinamica®, a microfiber fabric with a similar appearance to suede, obtained in part by an innovative polyester recovery process, initially used in the furniture and fashion sectors.

Subsequently, becoming part of the Sage Automotive Interiors Group (USA), controlled by the Japanese Ashai Kasei Corporation, Miko expands its offer by entering the demanding automotive market.

To support the plans of continuous development, the important project of a new finishing line over 70 meters long has recently been finalized, in which different processes are carried out that synergistically contribute to the achievement of the exclusive characteristics of the Dinamica® fabric: the dyed fabric is first treated with the new Kinetika which, thanks to the particular patented high-pressure spraying technique, effectively extracts color residues and removes excess products used in previous processing phases.

The high washing power of Kinetika, which applies not only the external surfaces but also deeply reaches the internal layers, is essential to ensure optimal conditions for the subsequent application of products that increase the functional performance of the fabrics (stain-resistant, fireproof, etc.). Miko’s technical staff has selected the innovative Kinetika solution following numerous tests that have highlighted the possibility of significantly increasing productivity allowing a drastic reduction in consumption.

Şark Mensucat, founded in Istanbul by the Bitlis family in 1956 has been able to combine and strengthen the synergy between experience and quality.

Şark Mensucat since 2005 has moved its operations to its new plant in Tekirdağ Çerkezköy with the daily goal of providing the best quality and professional service to its customers, investing every year in infrastructure, machinery modernization and automation.

Thanks to its know-how, Sark Mensucat is an experienced and reliable partner of global brands and contributes to creating value for the processed fabrics through innovative dyeing and finishing techniques that are carried out by highly qualified personnel who are aware of their responsibility to customers, society and the environment.

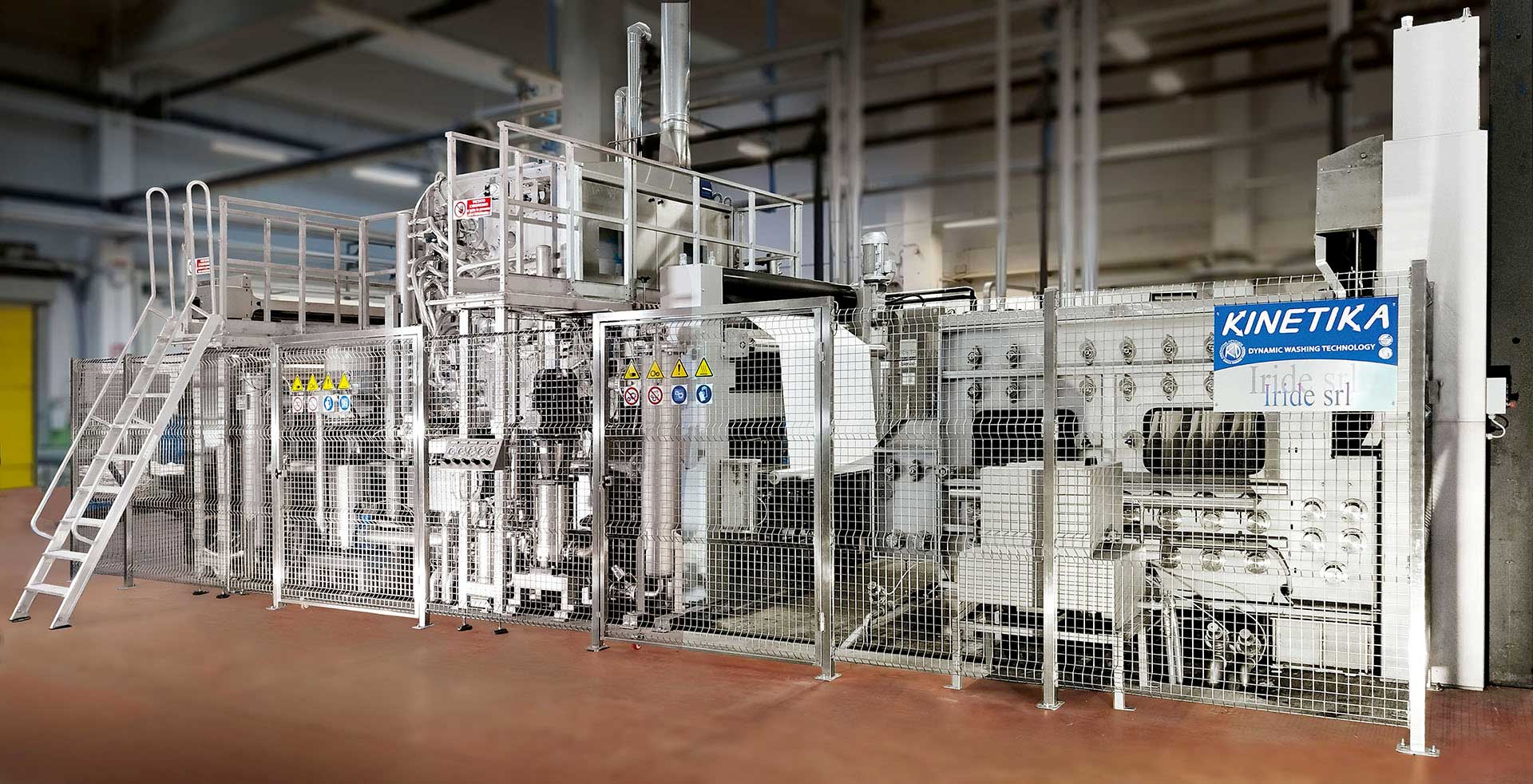

Iride srl (Biella) is a company active in the dyeing and finishing of fine fabrics, which in recent years has carried out an extensive investment program in technological innovation, guided by principles of energy efficiency and sustainability, such as the study of natural dyes.

The most recent investment is the Kinetika continuous washing plant, which features a revolutionary patented operating principle, in which the fabric is washed by high-pressure jets of fluid along a path created by a pair of permeable conveyor belts.

The washing line consists of 4 modules:

- double impregnation tank with 'Vortex' system of forced liquor circulation through the fabric by means of submerged suction bars

- Kinetika high-pressure washing unit with permeable transport belts

- multi-roller tank for steam or water treatment

- module of 8 heated cylinders for drying the fabric

Botto Giuseppe e Figli S.p.A. has been producing fine yarns and fabrics since 1876. Today, the fourth generation of the family runs an international business with many of the world’s most prestigious luxury customers. Almost 150 years of tradition and history are embodied in products that combine beauty and research.

In a rare and final example of a vertical supply chain, all production operations have been kept in Italy, with all washing, combing, spinning, dyeing, warping, weaving and finishing operations carried out entirely in-house.

Botto Giuseppe e Figli S.p.A. has invested in renewable energy and energy-saving measures to reduce its environmental impact. Its products are made from natural, renewable, biodegradable raw materials, and are manufactured using sustainable production processes. The company is currently implementing the use of recycled raw materials in its production processes.

The decision to invest in a new Kinetika fabric washing plant is consistent with the principles of sustainability and innovation that distinguish Botto Giuseppe’s identity.

In Kinetika the interaction between fluid and fabric (technically defined as “exchange”) is achieved in an innovative way characterized by unrivalled kinetic force, thanks to which optimized results are achieved in terms of both water, energy and steam consumption reduction and washing performance.

Thanks to the action of the conveyor belts, the fabric is not subject to stretching or creasing, making Kinetika suitable for treating a wide range of fabrics, from the lightest and most delicate to the heaviest and thickest.